I have spent thousands of hours sanding wood. If I could only impart one tip to all woodworkers regarding how to sand wood, it would simply be this,

SAND THE SEQUENCE.

Most woodworkers know the secret to a quality finish for any woodworking project is great sanding. If you can resist the urge to start with a higher grit, and start with 80 grit and sand the sequence, it will always save time. Don’t jump ahead and don’t skip steps. I’ve done this and it always ends up taking longer, costing more in abrasives, and it’s frustrating trying to achieve the desired results. These two videos are an introduction to understanding sandpaper and sanding theory. They are the synthesis of my experience to produce the best sanded surface in the least amount of time, for the least amount of money and effort.

What is Sanding The Sequence?

Sanding using each of the grits below in succession.

80 • 100 • 120 • 150 • 180 • 220 • 320

When you start sanding wood using 80 grit you quickly set the shape and remove machine marks, embedded glue and level uneven joint surfaces. Then you continue sanding using 100, 120, 150, 180, 220, 320 without skipping any of the sequence. Remember, after this initial shape is set with 80 grit then all the other subsequent sanding grits are only removing the previous grits sanding marks. So, you are not trying to remove material any more, you are only polishing the wood. This is crucial to understand.

Half Sheet Sanders

Save Money Buying Sandpaper

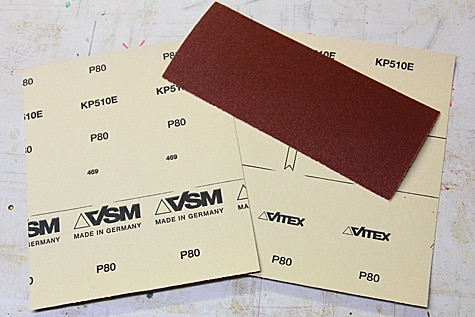

The best way to purchase sandpaper isn’t at your local hardware store, it’s buying online or at an industrial supply store. Making this one change can save you lots of time and money. I always buy full sheets of paper and cut them down into half sheets myself. (video shows this simple technique). The two types of paper I use and recommend are Mirka and VSM Vitex. I buy Mirka from BeaverTools.com and you can get VSM Vitex from VerySuperCoolTools.com. Buying paper 5 sheets at a time pre-packaged is not the most economical way to buy sand paper.

WoodMan’s Tips For Sanding Wood:

- Sand the sequence

- Use a half sheet sander

- Buy quality sandpaper in full sheets (Woodman recommends VSM Vitex and Mirka)

- Watch my videos for many more tips and tricks

Have a question that wasn’t covered? Please Ask Woodman in the comment box below. I will be happy to answer you!

Hi, Alan. I just want to thank you for sharing really useful sanding tip. I’m newbie and first I don’t know about sanding work but through this post I learn a lots. thanks again.

Hello,

In first time a must say: Thank You, You make wery good job and learned so much for your videos!

Allan, I wrote you earlier about “sanding the sequence.” I appreciate your reply and advise. I have now found your video on this subject. I own a Porter Cable 6″ rotary sander that you poke at in one your videos :-). Actually it performed well on an exterior door to be painted. However, I am writing to tell that I began looking for a half sheet sander. I cannot afford a Festool product and was a bit flummoxed. Then I went to a sell off by a going out of business shop and found a PC 505 that did not work. Bought it for $5.00!!! In five minutes found that the power cord had a break in a wire. New cord, new felt pad, twenty minutes of maintenance and $45 dollars later (I also bought a PSA pad for it) I am in business with a half sheet sander with a fine pedigree, if a rather non-existent dust collection system. I am stoked to try it out!

Kevin Fermenick

Hay Alan, I would just like to thank you for all of your great advice you share in your videos. I just bought a 1/2sheet finish sander Mikita and vitex paper. It has taken my work to a whole new level thanks again. BillPoplaski

Thanks Bill, I know a half sheet sander is never going to win any stock removal race, but it just gets your work done without making mistakes or a mess. I am glad to hear you are happy with the VSM/Vitex. You will now compare all other paper to it, and no other paper I have ever seen holds up and performs so well. Thanks for writing and Merry Christmas and all the best to you and yours in 2013. Allan

Woops! Another general rule in life is to always proof your mail before you send it. As you see, I have three questions.

Jay

Three questions:

1) I purchased a fancy mahogany door with lots of carving and raised portions around the circular window. Some of the raised portion is rough enough that I may need to add some filler. What material would you recommend if the door will be sealed with Waterlox;

2) What sandpaper do I use to get around these rounded pieces while maintaining the design curves;

3) All of the flat portion is relatively smooth. Do I still start my sequence at 80? Seems like I would be taking a step backwards by creating wigglies in the wood that is already equivalent to what it might look like after having been sanded to one of the light to middle grits.

If you like, I can send detail photos of the door.

Thanks

Jay, Send me a pic of your door and I will give you my number and we can have a chat about your door. Use my askwoodman@nullgmail.com address. Allan

Hello,

Building some plywood cabinets with birch 3/4″ and will probably just do a polyurethane finish. As the wood has a very smooth finish already, and the veneer is thin, I didn’t want to start too rough and end up blasting off the veneer. What sanding sequence would you suggest for this scenario.

Roger.

I would take a piece of the plywood scrap and do a sanding test to see where you need to start. Many plys have the “onion skin” veneer so you may only be able to do a 220 and 320 before breaking through. You want to end up at least 220 but there is no way to sand the sequence, so you are just going to have to do a scientific experiment to see how much your particular ply can be sanded.

I have a single rpm(12,000) 1/2 sheet sander and it seems to be really difficult to stop wanting to jump around any ideas as to where I (or the machine) might be going wrong?

“A well sanded and finished 2×4 stud looks better to me than a piece of rosewood with planner ripple and sanding swirl marks covered in a polyurethane finish.” ~ Allan Little

This quote expresses very nicely one of the first things I learned when I took up woodworking as a hobby several years ago. One of my early projects was to build a desk out of standard 2x4s cut in half to 2x2s creating sort of a butcher block design. No one was able to tell it was made of 2x4s and not high quality pine.

I found your site and YouTube videos while seeking info on proper sanding techniques, and I couldn’t be more impressed with yours. Thank you very much for sharing this with the rest of us.

I have been trying to get panels of Sapele properly sanded for weeks, (many hours of actual work) without satisfactory results. This is why I went to the web for ideas. For some reason, I cannot get all of the scratches out. I started with a belt sander with 80 grit, then went to a 5″ random orbital sander with 80, 120, 220 and 320, yet some of the scratches just will not go away. I purchased a 1/4 sheet sander yesterday, (no one open had a 1/2 sheet so I ordered a Bosch from Amazon before I read your posts) and will start over at 80 and see if that works. Any ideas why I am not getting the results after so much sanding? Do you think it is due to the improper tools?

Thanks again for sharing your experience with us.

I think I may know the cause of your sanding issues. The belt sander. Unless a belt sander is held in a sanding frame it is almost impossible to use a belt sander on a flat panel and get uniform depth of cut because of platen tilt. So I think you have belt sander scratches that are still so deep that the subsequent sanding operations you are doing are not sufficient. When your half sheet arrives you may have to start your sequence at an even lower grit than 80 and get those tops flat, and then methodically move through the sequence. 3M makes a black floor paper called Resonite that comes in rolls. My local hardware store sells just as many feet as I need (which is not that often). But you can cut it to fit your 1/2 sander and quickly set a fresh flat plane that gets rid of the belt sander tilt. Perhaps 60 grit in the 1/2. The beauty of the 1/2 is that it floats on the top and can’t tilt or gouge. I am happy to continue this conversation so please feel free to write me at askwoodman@nullgmail.com if you like. Pics always help me get a clear idea of projects. Plus I love to see what people are working on and to see peoples work areas. Keep in touch. Allan

I was look at one of your video on door finishing where you finished both side of a door. But the attachment which the door was secured to is what. That attachment enable you to turn that door on each side. Is that something i can make or purchase, please respond.

Thanks

It is really easy to make just with odds and ends from around the shop. Check out video 15 in The Solid Wood Door Series and I cover all the important points. Write me at askwoodman@nullgmail.com if you have questions I did not cover. Happy to help.

Hi Allan

I’m from South Africa – Cape Town.

I enjoyed you videos so much and all the articles. According to the Festool cataloge the Festool RS2 is replaced by the RS200 330watt. The RS100 is 620watt. Is the RS100 to heavy and to much for sequence sanding.

I’ve got 4 Festool sanders bu all orbital and I use the Rotex RO90 and Rotex RO150 for heavy removal and the EFT 125 and LS 130 for finishing. You persuade me to the RS 200 / 100 wich ever you think is the best.

I could not find a suppliers in SA for the Mirka or VSM Vitex sandpaper. Looks like Norton is the most wellknown brand here.

Regards

Bekker

Hi Bekker I have never been fortunate enough to travel to your beautiful country, but from what I seen Cape Town has to be one of the most stunning cities in the world. The video I have seen of the clouds dropping over the edge of Table Mountain must inspire awe no matter how many times one sees it. Ok let me snap out of my daydream and start thinking about sanders. I looked on Festool USA site and I did not see the new replacement sander you mentioned. The RS2E sold here in the US is a fantastic sander with all the features I want. I really can’t imagine Festool could improve it but they probably will. I bought the accessory urethane pad so I can use any regular paper and the the hole punch platten too. Feel free to write me at askwoodman@nullgmail.com and we can exchange pics and ideas a little easier. I think Norton paper is really good. I have it in my stock and think they make a really quality product at a fair price. Thanks for writing and keep in touch. Allan

Hi Allan,

Me again. Scratch my question. I should have read all the previous responses. I see that you are using the urethane pad (which I assume is what Festool describes as the StickFix pad).

Marty

Hi Marty, I bought the pad that has the side protectors on it. The side protectors have worn away at this point, but the pad is still in great shape, even after over 5 years.

Hi Allan,

Well, I’m ready to pull the trigger on the RS2. I was hoping that you could tell me if you bought the StickFix pad to use with your sandpaper, or are you using the hook & loop pad that came with the sander?

Thanks,

Marty

Dear Sir,

So happy to see such a website where you can get helpon woodworking. i am into small scale manufacturing of wooden temples, i feel am good at the art work ( designing)the temple, but i fail in finishing the temples (teak wood) i try the transparent polishing where i can see the grains. i fail to get the natural grains in dark shades of polishing. Is there any method you can suggest. pls help.

thanks ®ards

shailesh

Hi Shailesh, Sorry it took me a few days to get back to you but I was having password problems on my site. Teak is wonderful wood but it does have characteristics that make it difficult to work and finish. The natural oiliness really keeps many finishes from penetrating and bonding to the wood fibers. Tell me what types of finishes you have been using and what are the products available in your part of India other craftsmen are using for finishing. You can write me directly at askwoodman@nullgmail.com and perhaps send me some pics of the temples before and after finishing. And show me the ideal tone you would like to achieve. Again I apologize for the lateness of my reply. Best regards. Allan

Allan,

I am making a toy chest for my grandaughter, The end panels have a cutout to pick up the chest and move it around. What is the best way to sand the sutouts?

Hi John, You might try using some fabric backed sand paper which really conforms to any odd shape. You are talking about hand sanding, and it takes time and can be hard on your hands.

Allan-

Thank you for the quick response!

After reading what you have said I think I will try the RS2E. I don’t plan on using it as much as you do but it will get plenty of work. I have read some reviews that people say it’s their most used sander and favorite Festool tool. Pretty high praise.

Why do you prefer standard sand paper to the hook and loop systems? I am not fond of the hook and loop either but was just interested in your opinion.

Yes I will use you site when ordering – thanks for the tip!

Hi Bob,

Standard sand paper is so much cheaper than hook and loop paper. And also, hook and loop pads wear out really quickly and become irritating when the paper doesn’t stick properly to the pad. So you have the added expense of constantly replacing the hook and loop pads. I gave up on them many years ago. I do use PSA on my two random orbit sanders which I use occasionally.

I really appreciate you clicking through my site when ordering. Thanks again for the reading and commenting.

Allan –

First thanks for all the great information you provide with your videos.

I have been looking at the Makita BO4900 and the Festool RS2e snaders to purchase. At almost $200 more do you think the Festool is worth the difference in price? From what I’ve read they are both exellent but the one area I thnk the Festool might have an advantage is the paper changing. How easy is it to do on the RS2e? It looks like the clamping system is really easy, but I have never seen one in person.

Also, since I will be using my own paper would you recommend getting the pad used for that type of paper instead of the hook and loop pad?

Thanks again!

Bob

Hi Bob

My RS2E has been a workhorse for over five years without one issue. Rarely a day goes by when it is not used and many days it is for hour after hour. The clamping system is pure genius. Not only a spring loaded but there are tree pronged teeth on each bar that perforate the paper. The dust collection is so efficient I do not even wear a mask with the sander hooked up to my Festool vacuum. I have never been a fan of hook and loop sandpaper fastening systems. I have the urethane pad and the hole puncher that Festool sells as accessories. All that being said, Makita products are the best value in woodworking tools. There tools work and hold up in the most demanding situations. So depending on how much you are going to use this sander, perhaps a BO4900 with the savings going towards another tool may be good choice. Maybe you will do me the favor of clicking through my site to Amazon or Woodcraft on a purchase so I get a little bit. It does not change your price at all. For Amazon it is any item not just tools. I will be happy to chat with you more about this, and please let me know what you decide.

Hello!

I am having to redo my porch. Do your recommend the sequence of events for railings? That seems extensive. Thank you for you help.

My post was aimed at woodworkers or furniture makers. So you are right, for porch railings it does not translate to carpentry situations. Try an experiment with different grits of paper on your railings to determine what grit you should start and perhaps finish with. It also depends on whether you are staining or painting and what level of surface smoothness you are going for. My rule of thumb is the courser you start the quicker you will be done. For a porch you may just need 60 then 80. It also depends on hand sanding or power sander. Sanding in line with the grain by hand will produce a much better surface at lower grits than an electric sander that is oscillating and cutting across the grain and leaving a more torn surface and orbital swirl marks. And of course it depends on the kind of wood and its condition. And sandpapers vary wildly in quality and grade for intended application. Write me at my gmail address if you want to send me pics so I can better understand your project.

Allan: I have been watching your video’s and I am real impressed with the one on sanding sequence. In the sequence you showed the the Fastool 1/2 sheet pad sander vs the round orbital sander, what is the model number of the Fastool 1/2 sheet pad sander?

On another site, I found a Fastool catalog where they had a Fastool RS 2E Large Orbital

1/2 sheet sander, is this what you are using or is it a different model? If your model isn’t abailable any longer, what would you recommend in a 1/2 sheet pad sander?

Thank you.

Ed

Hi Ed, Yes that is the model I have. Mine is 5 years old and I have worked it like a rented mule and I can’t detect one bit of loss of performance. Since I don’t like hook and loop sandpaper and wanted the flexibility to use any paper I want I bought the accessories: 485647 replacement pad with edge protector, and 481523 hole punch. I use mine attached to a Festool vacuum and do not need to wear a mask while sanding, and the workpiece is practically clean after sanding. A half sheet sander does not sling dust like a random orbit sander does and more importantly does not get out of control and make mush of your hard work. If you do choose to buy this, perhaps you will consider clicking through my site to Woodcraft where I will make a little money without changing your price. You can click the Woodcraft banner of my site or just my Woodcraft affiliate link here: http://goo.gl/NyG2k Festool’s prices are exactly the same regardless of store.

I did a little research online for another 1/2 sheet sander if the Festool price is more than your want to pay. Makita has model BO4900V that looks really nice for $180 ready to go. I like Makita tools and have never been able to kill one of their products try as I might. I am not a fan of Bosch. Again I have an affiliate relationship with Amazon so if you choose to buy this sander or anything else I would appreciate if you clicked through my Amazon store on AskWoodMan.com or just click my Amazon affiliate link here: http://goo.gl/FfM3K Let me know what you decide and what kind of projects you are working on. I really enjoy getting pictures of projects and shops too.

Hi Ihab I would not consider myself an expert on painting compared to the transparent finishes where I have much more experience. If you are talking about paint. The most important aspect is priming. Sometimes I have to prime two or three times to get the surface ready for top coating. I always make my first coat of primer a thinned down primer wash to really get in and penetrate. I lightly sand between coats and make sure everything is really clean before applying the next coat. I usually prime with a brush and roller to really work the primer into the wood. For the top coats, spray, brush or roller. I always use an oil primer but the top coats vary. Latex for exterior since it won’t mildew like oil paints can and oil enamel for interior. I always add a paint conditioner also: Penetrol for oil and Flotrol for latex. These make the paint cover and work better. I am happy to continue this conversation. You may also write me at Askwoodman@gmail. I enjoy getting pictures of peoples work and workshops also. Keep in touch. Allan

Dear Sir,

First of all I would like to thank for helping the people who need the help.

I have a workshop in Suadi Arabia for wood doors and always face us some problem in the finishing (Painting).

Please if you have standard details for the painting to use because I’m not satisfied with the quality provided to my customer so please can you send it to me

Thank you

Ihab Mansour